- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

- Wafer Concentric Butterfly Valve

- Lug-Wafer Concentric Butterfly Valve

- Flange Concentric Butterfly Valve

- Double Eccentric Butterfly Valve

- Bronze Butterfly Valve

- Ball Valve

- Concentric Butterfly Valve

- PTFE Lined Butterfly Valve

- Gate Valve

- Globe Valve

- Butterfly Valve

- Cryogenic Valve

- Check Valve

- Automatic Control Valve

- PTFE Lined Valve

- Aluminum Bronze Valve

- Strainer Valve

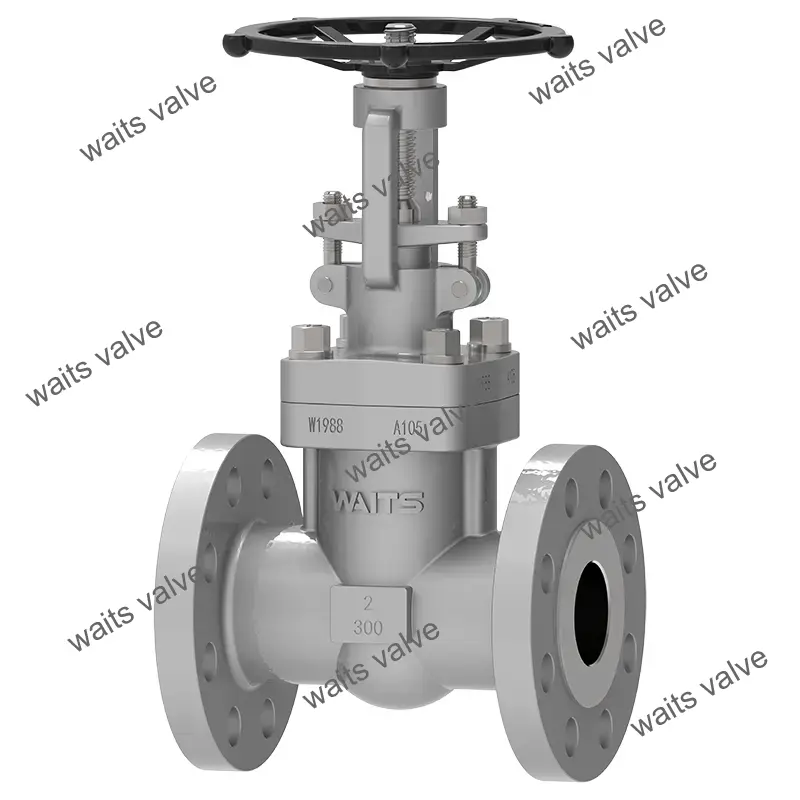

Flanged Forged Steel Gate Valve

Waits is your reliable choice for purchasing flanged forged steel gate valve. We have many years of industry experience, the industrial chain can be mass-produced, the supply is stable, the price is good, and the sales are good in the Middle East and North America. The product is made of high-quality forged steel, with good sealing, durability, easy operation, and can accurately control the flow of media, suitable for a variety of industrial pipeline systems.

Send Inquiry

The quality of forged steel parts is higher than that of cast steel parts, and they can withstand the impact of beatings. The plasticity, toughness and other mechanical properties are also higher than those of cast steel parts. The diameter of flanged forged steel gate valves is generally not more than DN80, and most of them are reduced diameter designs. Compared with cast steel gate valves of the same diameter, the flow rate is slightly smaller, but the pressure and temperature range they can withstand are higher than those of cast steel valves, and the sealing performance is much better than that of cast steel gate valves, and the service life is longer. The flow direction of the medium is not restricted like other gate valves.

Implementation Standards

| Design Standard | API 602, GOST |

| Flange standards | SW Socket welding ends according to ASME B16.11, BW butt end by ASME B16.25, NPT threaded connectors according to ASME B1.20.1 |

| End Connection | SW, NPT, BW, RF, RTJ, etc. |

| Inspection & Test | API 598 |

| Face to Face | ASME B16.10, GOST |

| Pressure and temperature levels | ASME B16.34 |

| Low leakage standards | ISO 15848-1, API 622 |

| Anti-corrosion design | NACE MR 0103, NACE MR 0175 |

Application

| Size | 1/4"-3", DN6-DN80 |

| Pressure Rating | Class 150-2500, PN10-PN420 |

| Operating Temperature | -60°C~450°C |

| Application range | Tap water, sewage, construction, petroleum, chemical industry, food, medicine, textile, electricity, shipbuilding, metallurgy, energy system, etc. |

| Operator | HW, Electric, Pneumatic |

| Body Material | Carbon Steel, Stainless Steel, Duplex Stainless Steel, Alloy Steel, Monel, Al Bronze, etc. |

| Valve plate/valve seat | A105, A350 LF2, A182 F5, F11, F22, A182 F304 (L), F316 (L), F347, F321, F51), Alloy 20, Monel |

| Valve stem | F6A F304 F316 F51 F53 Monel K500... |

| Valve stem nut | Copper alloy... |

| Packing | Flexible graphite, graphite asbestos packing, polytetrafluoroethylene... |

Performance Features

1. The main components are forged. Flanged forged steel gate valve have three types of middle cavity seals: bolted bonnet, welded bonnet and middle cavity pressure self-tightening seal structure.

2. Bolted bonnet means that the valve body and bonnet are connected with bolts and nuts, and sealed with a spiral wound gasket (made of stainless steel wire clips and flexible graphite). Metal ring connection can also be used when customers have special requirements.

3. Welded bonnet means that the valve body and bonnet are connected with threads and fully welded. Fully welded connection can also be used when customers have special requirements.

4. The middle cavity of 900Ib, 15001b, and 25001b adopts a pressure self-tightening seal structure, and the sealing performance increases with the increase of internal pressure, with high reliability.

5. The channel is smooth and the flow coefficient is small. The sealing surface is less eroded and eroded by the medium.

6. The sealing surface is made of alloy steel or hard alloy, with good wear resistance and abrasion resistance.

7. Flexible graphite filler is used, the sealing is reliable, and the operation is light and flexible.

8. The medium flow direction is not restricted, there is no disturbance, and the pressure is not reduced.

9. The packing replacement and maintenance can be carried out in the state of online shutdown, which is convenient and fast without affecting the operation of the system.

10. The shape is simple, the structure length is short, the manufacturing process is good, and the application range is wide.