- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

- Wafer Concentric Butterfly Valve

- Lug-Wafer Concentric Butterfly Valve

- Flange Concentric Butterfly Valve

- Double Eccentric Butterfly Valve

- Bronze Butterfly Valve

- Ball Valve

- Concentric Butterfly Valve

- PTFE Lined Butterfly Valve

- Gate Valve

- Globe Valve

- Butterfly Valve

- Cryogenic Valve

- Check Valve

- Automatic Control Valve

- PTFE Lined Valve

- Aluminum Bronze Valve

- Strainer Valve

China PTFE Lined Valve Manufacturer, Supplier

- View as

PTFE Lined Wafer Check Valve

Waits Valve PTFE Lined Wafer Check Valve features corrosion resistant, high quality PTFE lining and compact design for reliable backflow prevention! Waits Valve adheres to transparent and pragmatic pricing, clearly listing six cost components, including casting, processing, inspection and other fees.

Read MoreSend InquiryPTFE Lined Diaphragm Valve

If you are buying Waits Valve high quality PTFE Lined Diaphragm Valve for the first time, we provide a friendly guide service for beginners. We have written a lot of articles on valve features and maintenance guidelines. These resources not only help customers choose the right valve, but also serve as an "encyclopedia" for novice valve engineers. Choose us and you will have a reliable supplier!

Read MoreSend InquiryPTFE Lined Angle Globe Valve

Waits Valve is a leading manufacturer of PVDF, FEP, PFA and PTFE lined globe valves in China. The PTFE Lined Angle Globe Valve features a PTFE anti corrosion lining, precise flow control and space-saving tilting! Waits Valve keeps 200 standard models in stock and can ship within 72 hours of receiving an order.

Read MoreSend InquiryPTFE Lined Globe Valve

Waits Valve is a large valve manufacturer and integrated supplier. Among them, PTFE Lined Globe Valve is our flagship product. With a large inventory and huge market demand, we are confident in our delivery capabilities. If you start a cooperation with us, please rest assured to entrust all to us! We will definitely give you a satisfactory service and price!

Read MoreSend InquiryPTFE Lined Gate Valve

Waits Valve is a compliant and well formulated PTFE Lined Gate Valve supplier. We hold ISO9001 certification and third party factory inspection reports, and provide clear certificates of origin, material reports and other basic documents. I believe that with our more than 30 years of experience in valve manufacturing and exporting, we are qualified to be your partner!

Read MoreSend Inquiry

Processes for Manufacturing Waits Fluorine-Lined Valves

1. Isostatic Molding Method

The isostatic molding method refers to a forming process that achieves the lining effect under the condition of equal pressure difference between the inner and outer walls of all lined parts of the workpiece. The biggest difference between this molding method and traditional compression molding lies in achieving the condition of equal pressure difference between the inner and outer walls of the workpiece's lined parts during the pressing process.

2. Compression Molding Process

The compression molding process employs medium-particle-size suspension polytetrafluoroethylene (PTFE) resin as the material. Molding initiates at approximately 19-22°C; higher temperatures may lead to material agglomeration, and precise temperature control is crucial to eliminate internal stress during this stage. Pressure is typically regulated at 350 kg/cm² and sustained according to the workpiece's size and shape. The process concludes with a three-stage sintering procedure—heating, holding, and cooling—after which machining is performed to achieve the desired specifications.

3. Transfer Molding Process

The transfer molding process involves placing the quality Waits valve body and the lining material together in a high-temperature sintering furnace for heating. After heating to a certain temperature, the body is taken out, and the lining material is slowly transferred to all parts of the lined body under the pressure of a press. This forming method is called transfer molding.

Fluorine-lined valves are classified as follows:

Pinch valves, lined diaphragm valves, lined pneumatic butterfly valves, lined pneumatic ball valves, lined check valves, fluorine-lined globe valves, lined plug valves, lined wedge gate valves, diaphragm valves, butterfly valves, ball valves, swing check valves, ball core check valves, pneumatic rubber-lined valves, fluorine-lined plastic diaphragm valves (normally closed type), straight-through fluorine-lined diaphragm valves, packed adjustable fluorine-lined plastic butterfly valves, fluorine-lined plastic globe valves, etc.

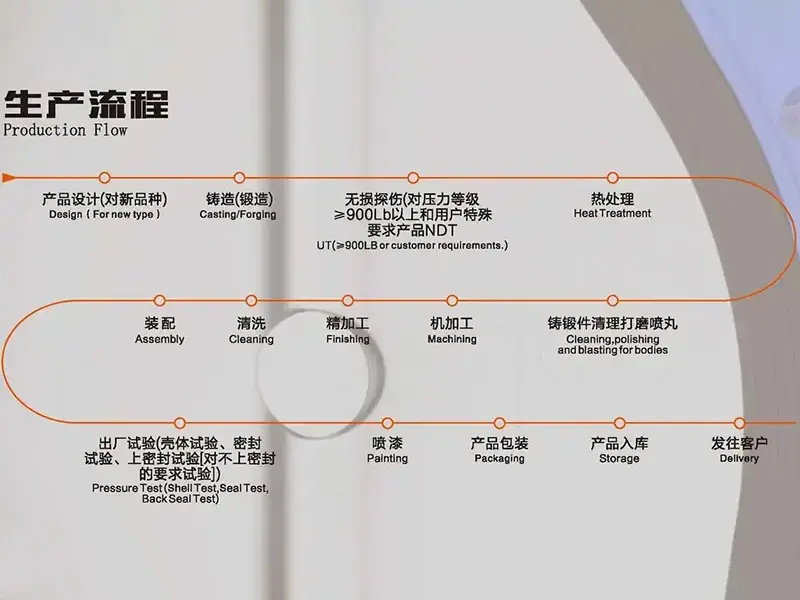

Production Process Management of Waits Valve

Waits Valve builds strong service and quality systems using practical methods. We follow strict industry standards like API 6D and CE-PED, and use ISO quality (9001), environmental (14001), and safety (45001) systems in all production steps. This ensures consistent operations and full tracking of every product.For quality checks, we use modern pressure-testing machines to verify valve strength. Smart inspection tools carefully check important parts like surfaces and seals to prevent quality issues. By combining strict management with detailed testing, we create reliable fluid control solutions for industries.

For more product details or technical assistance, please contact our expert team at any time.