- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

- Wafer Concentric Butterfly Valve

- Lug-Wafer Concentric Butterfly Valve

- Flange Concentric Butterfly Valve

- Double Eccentric Butterfly Valve

- Bronze Butterfly Valve

- Ball Valve

- Concentric Butterfly Valve

- PTFE Lined Butterfly Valve

- Gate Valve

- Globe Valve

- Butterfly Valve

- Cryogenic Valve

- Check Valve

- Automatic Control Valve

- PTFE Lined Valve

- Aluminum Bronze Valve

- Strainer Valve

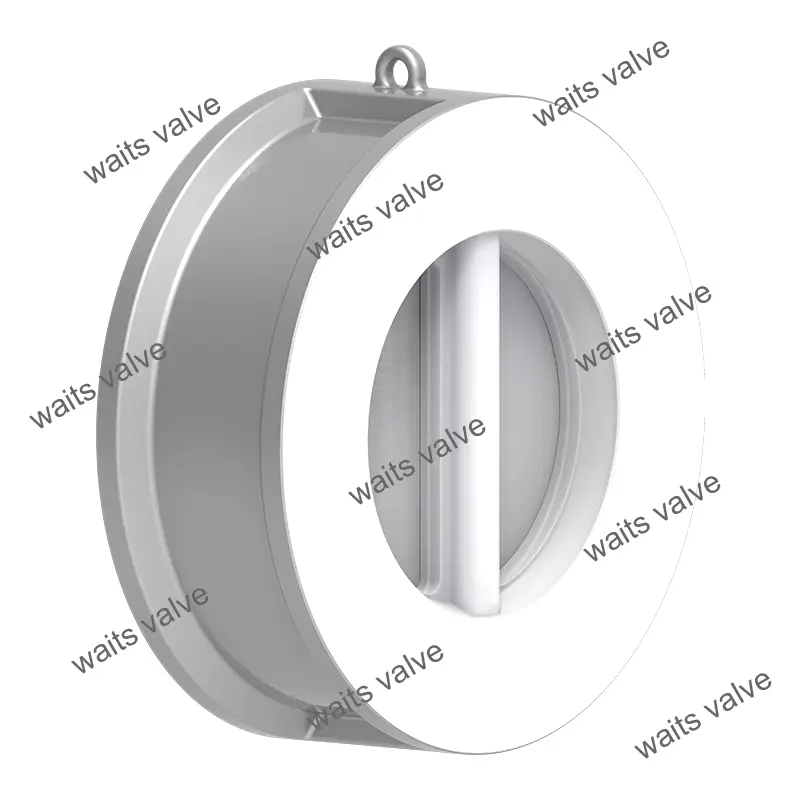

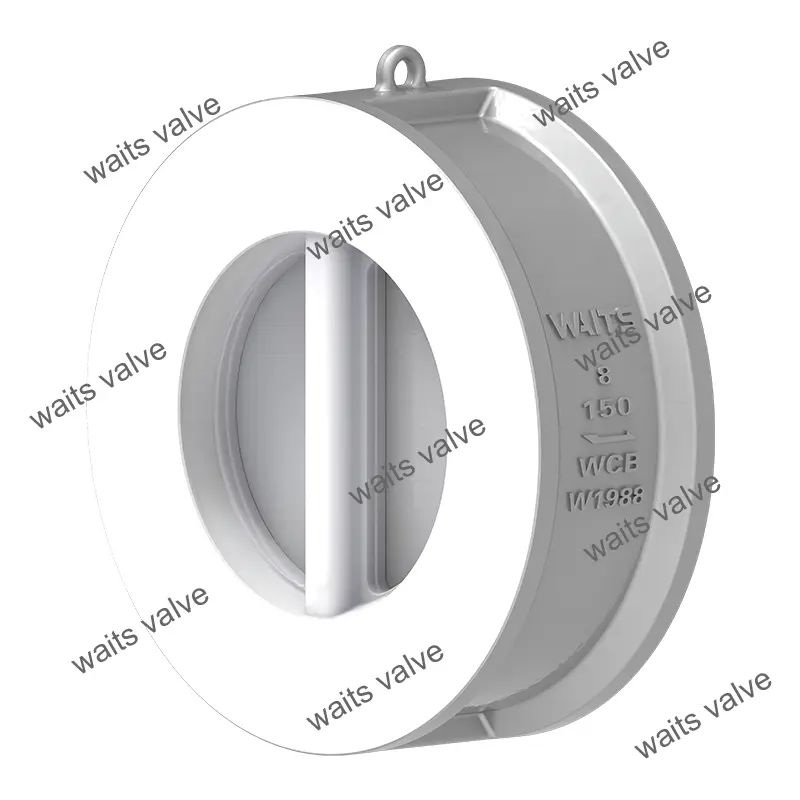

PTFE Lined Wafer Check Valve

Waits Valve PTFE Lined Wafer Check Valve features corrosion resistant, high quality PTFE lining and compact design for reliable backflow prevention! Waits Valve adheres to transparent and pragmatic pricing, clearly listing six cost components, including casting, processing, inspection and other fees.

Send Inquiry

Manufactured in the Waits Valve factory in China, the PTFE Lined Wafer Check Valve prevents media backflow through a combination of fluoroplastic lining and check mechanisms (such as valve discs, diaphragms, springs, etc.). Its core feature is that the inside of the valve body and the sealing surface are coated with fluoroplastic to isolate the media from the metal parts. These valves are suitable for pipeline systems that convey highly corrosive, high purity or easily contaminated media, and are widely used in chemical, pharmaceutical, electronic, environmental protection and other industries.

All our valves are molded with PFA linings, which are compatible with the most corrosive and toxic chemicals. They can all be used at temperatures up to 392°F.

Our check valves are used in a wide variety of process lines and are often used to:

Maintain static head pressure at pump outlet

Prevent product batch contamination

PTFE Lined Wafer Check Valve provides simple nitrogen blanketing control

We are confident we can find the right valve for your application.

| Implementation Standards-PTFE Lined Wafer Check Valve | |

| Design Standards | API 6D/API594/BS1868 |

| Flange Standard | ASME B16.5/ASME B16.47-A/B /EN1092-1/2 |

| Connection methods | Wafer, FF, RF |

| Testing and acceptance | API 598, EN12266 |

| Structural length | API6D/ASME B16.10/EN558 |

| Pressure and temperature ratings | ASME B16.34 |

| Fireproof test | / |

| Low leakage standards | ISO 15848-1, API 622 |

| Anti-corrosion design | NACE MR 0175 |

| Application-PTFE Lined Wafer Check Valve | |

| Size | NPS 2”~ NPS 12″ DN50 ~ DN300 |

| Pressure range | CL150 ~CL150 PN10~ PN16 |

| Temperature range | PTFE-50°C~+180°C |

| Application range | Suitable for water, steam oil, nitric acid, acetic acid, strong oxidizing media and other media. |

| Valve body |

Forgings: A105, A182 F304, F304L, F316, F316L, F51, F53, B148, A350 LF2, LF3, LF5, Monel, PTFE-lined Castings: A216 WCB, CF3, CF8, CF3M, CF8M, 4A, 5A, C95800, LCB, LCC, LC2, PTFE-lined |

| Valve plate | Metal, PTFE-lined |

| Filler | PTFE (F4) or reinforced graphite |

Product Features

1.Wafer Type Design:Flat ends for installation between two pipeline flanges, secured by bolts (no welding or additional flange accessories required).

2.Working Principle:

Forward flow: Medium pressure pushes the disc open.

Reverse flow: Disc closes automatically, with the PTFE sealing surface preventing backflo

Product Advantages

1.No separate flanges required, reducing material usage and cost compared to flanged types.

2.Simply loosen bolts for maintenance without moving pipes, good for space constrained areas (e.g., densely packed pipelines).

3.Short disc travel distance, suitable for high flow, low viscosity media (e.g., water, solvents).