- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

- Wafer Concentric Butterfly Valve

- Lug-Wafer Concentric Butterfly Valve

- Flange Concentric Butterfly Valve

- Double Eccentric Butterfly Valve

- Bronze Butterfly Valve

- Ball Valve

- Concentric Butterfly Valve

- PTFE Lined Butterfly Valve

- Gate Valve

- Globe Valve

- Butterfly Valve

- Cryogenic Valve

- Check Valve

- Automatic Control Valve

- PTFE Lined Valve

- Aluminum Bronze Valve

- Strainer Valve

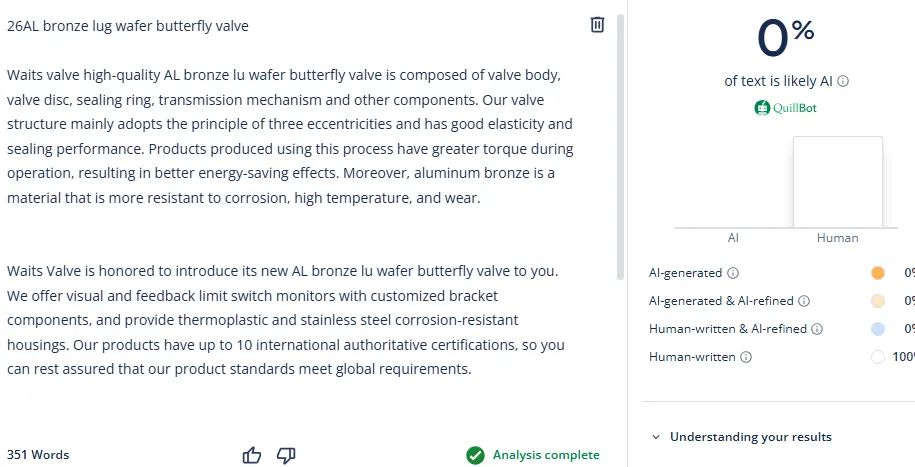

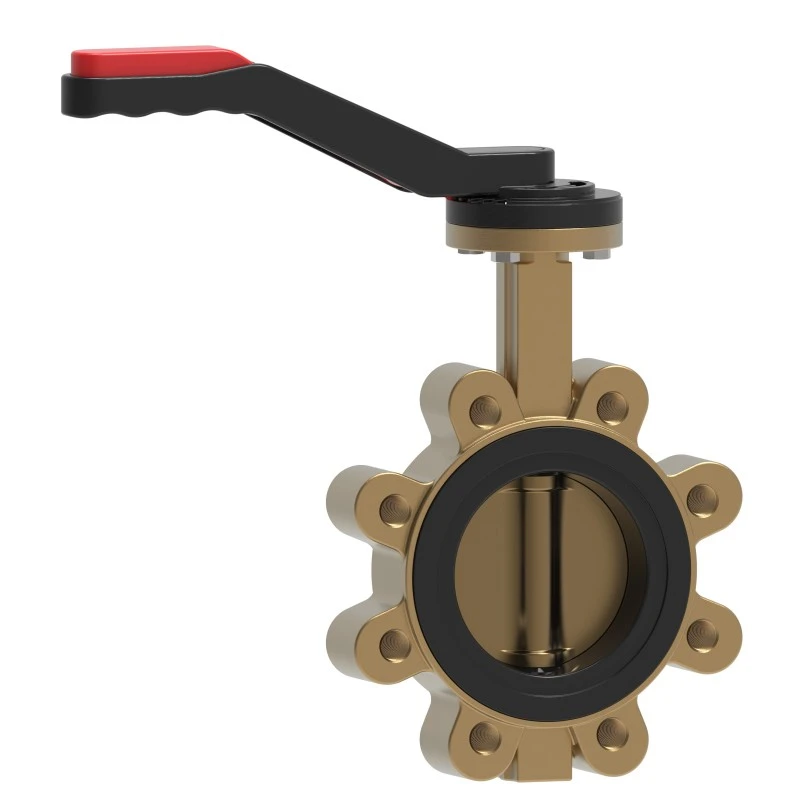

AL Bronze Lug Wafer Butterfly Valve

Waits valve high-quality AL bronze lug wafer butterfly valve is composed of valve body, valve disc, sealing ring, transmission mechanism and other components. Our valve structure mainly adopts the principle of three eccentricities and has good elasticity and sealing performance. Products produced using this process have greater torque during operation, resulting in better energy-saving effects. Moreover, aluminum bronze is a material that is more resistant to corrosion, high temperature, and wear.

Send Inquiry

Waits Valve is honored to introduce its new AL bronze lug wafer butterfly valve to you. We offer visual and feedback limit switch monitors with customized bracket components, and provide thermoplastic and stainless steel corrosion-resistant housings. Our products have up to 10 international authoritative certifications, so you can rest assured that our product standards meet global requirements.

The AL bronze lug wafer butterfly valve is designed for ship, nearshore, and corrosive water applications, and this special material enhances the lifespan of the valve. This valve is made of advanced aluminum bronze (C95400/C95800) and is a choice for harsh environments that cannot be met by seawater cooling systems, seawater desalination plants, and other standard materials.

Detail:

This series of AL bronze lug wafer butterfly valves adopts a central valve disc and flange type clamping structure, made of bronze aluminum material, suitable for marine applications.

At present, aluminum bronze valve discs and nitrile rubber lining versions are available, with code L9.771.

Specifications range from DN40 to DN300, PN16 standard (Pn6/10/ANSI150 standard can be provided upon request).

Working temperature: -10~+80 ° C.

Each version can be customized with different control modes: lever type, manual gearbox, pneumatic and electric actuators.

Why choose Waits valve?

Firstly, we have a professional quality control team and advanced testing equipment, so all of our products have quality assurance. You don't have to worry too much about it

Secondly, our delivery time is very timely. We can rely on highly trusted raw material suppliers and streamline complex production processes, so we can definitely deliver on time.

Finally, we have excellent after-sales service, with our team of valve experts providing all technical and after-sales support.