- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

- Wafer Concentric Butterfly Valve

- Lug-Wafer Concentric Butterfly Valve

- Flange Concentric Butterfly Valve

- Double Eccentric Butterfly Valve

- Bronze Butterfly Valve

- Ball Valve

- Concentric Butterfly Valve

- PTFE Lined Butterfly Valve

- Gate Valve

- Globe Valve

- Butterfly Valve

- Cryogenic Valve

- Check Valve

- Automatic Control Valve

- PTFE Lined Valve

- Aluminum Bronze Valve

- Strainer Valve

Semi Lug Butterfly Valve

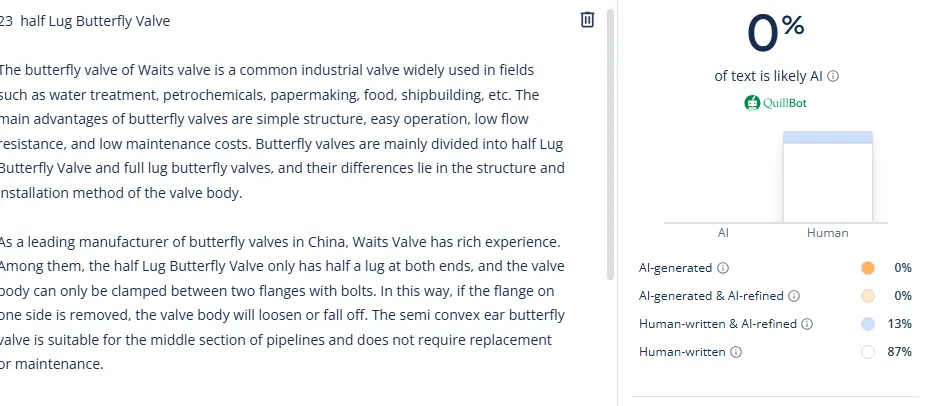

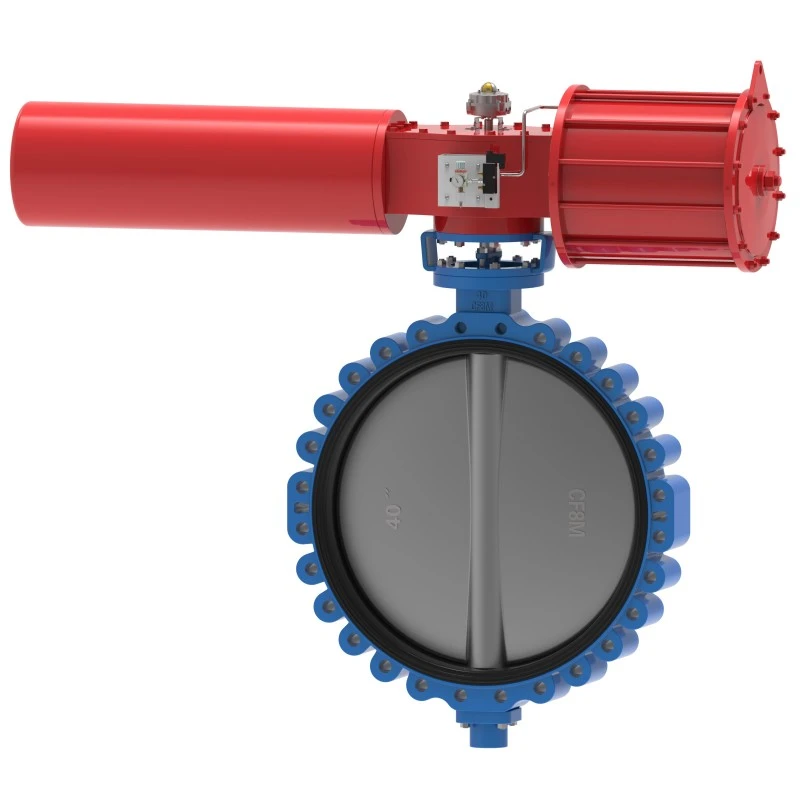

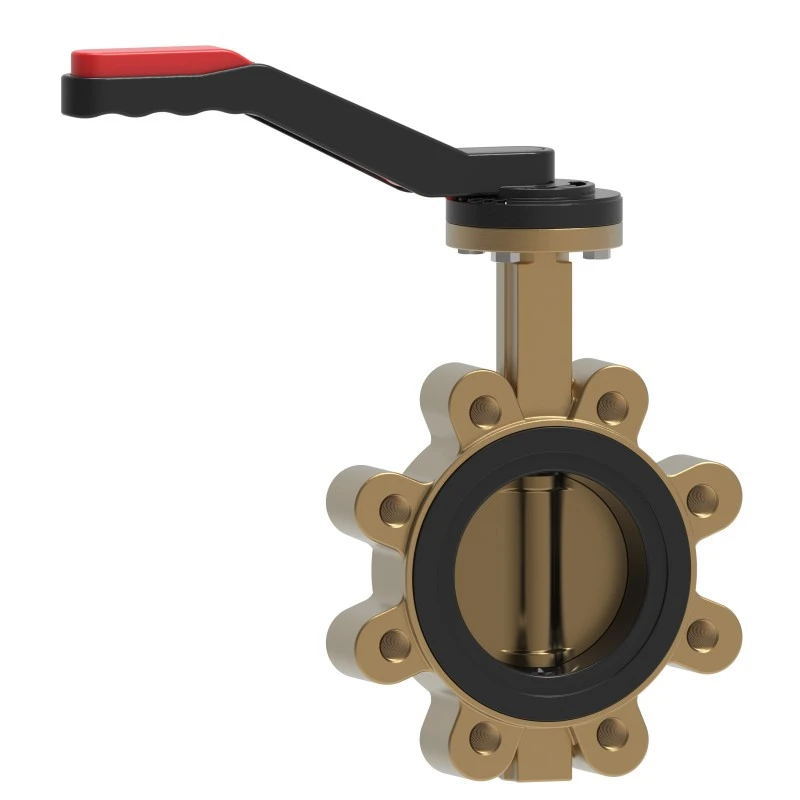

The butterfly valve of Waits valve is a common industrial valve widely used in fields such as water treatment, petrochemicals, papermaking, food, shipbuilding, etc. The main advantages of butterfly valves are simple structure, easy operation, low flow resistance, and low maintenance costs. Butterfly valves are mainly divided into half Lug Butterfly Valve and full lug butterfly valves, and their differences lie in the structure and installation method of the valve body.

Send Inquiry

As a leading manufacturer of butterfly valves in China, Waits Valve has rich experience. Among them, the half Lug Butterfly Valve only has half a lug at both ends, and the valve body can only be clamped between two flanges with bolts. In this way, if the flange on one side is removed, the valve body will loosen or fall off. The semi convex ear butterfly valve is suitable for the middle section of pipelines and does not require replacement or maintenance.

Feature:

The half Lug Butterfly Valve is similar to a clamp type butterfly valve, but has a pair of threaded bolt holes on each side for easy maintenance of adjacent pipelines.

Easy to operate and lightweight.

Less holes and easy installation.

When repairing adjacent pipelines, it can prevent liquid residue.

Double eccentric high-performance semi convex ear type

Detail:

The rotation axis of the valve disc is offset from the valve seat ring in a double eccentric manner.

When the valve disc rotates, it disengages from the valve seat at a smaller angle through the cam effect.

Half Lug Butterfly Valve can prevent valve seat wear and maintain perfect sealing for a long time.

Pipeline system application:

Oil tanker - shipbuilding

Offshore/onshore factories, oil and gas

production platform

Chemical and petrochemical plants

Water treatment and purification

Steel and metal plants

Military applications

foundry

Pulp and paper mills

food factory

textile industry

Sugar Factory

Fireproof pipeline system