- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

- Wafer Concentric Butterfly Valve

- Lug-Wafer Concentric Butterfly Valve

- Flange Concentric Butterfly Valve

- Double Eccentric Butterfly Valve

- Bronze Butterfly Valve

- Ball Valve

- Concentric Butterfly Valve

- PTFE Lined Butterfly Valve

- Gate Valve

- Globe Valve

- Butterfly Valve

- Cryogenic Valve

- Check Valve

- Automatic Control Valve

- PTFE Lined Valve

- Aluminum Bronze Valve

- Strainer Valve

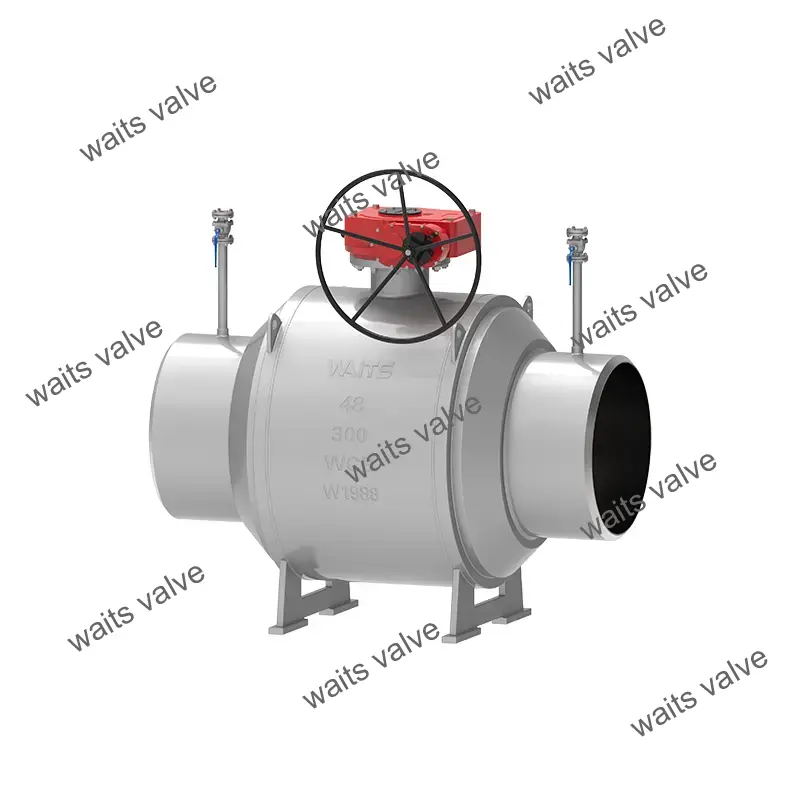

Fully Welded Ball Valve

Waits is a large valve manufacturer, and fully welded ball valve is one of the products we can provide. Since the valve seat of this product is composed of carbonized Teflon sealing ring and disc spring, it has strong adaptability to changes in pressure and temperature and will not leak within the marked pressure and temperature range. In gas transmission projects in the Middle East and heating projects in Northern Europe, fully welded ball valves are widely used.

Send Inquiry

Fully welded ball valve is a commonly used ball valve product. It can use oil pressure or pneumatic force to control the rotation of the ball to open and close and adjust the flow rate. In terms of performance, it is corrosion-resistant, reliable in sealing, easy to open and close, and has a wide range of flow regulation. Therefore, it is widely used in the fields of petroleum, chemical industry, natural gas, papermaking, water treatment and electricity.

The fully welded ball valve produced by Waits has excellent performance, compact structure, easy operation and long service life, all of which have passed our strict quality inspection system. During use, you can select the model according to factors such as media and operating conditions, and maintain the operating status of the ball valve through correct installation and operation, as well as subsequent regular inspection and maintenance. If you encounter problems, or want to know more about the product or the latest factory price, you can contact us at any time for communication and service support.

Implementation Standards

| Design standards | API 6D ISO14313, DIN 3357-1 |

| Flange standards | ASME B16.25, EN 12627 |

| Connection methods | BW |

| Testing and acceptance | API598, API6D, EN 12266 -1 |

| Structural length | ASME B16.10, DIN3202, |

| Pressure and temperature ratings | ASME B16.34、 |

| Fireproof test | API607, API6FA |

| Low leakage standards | ISO 15848-1, API 622 |

| Anti-corrosion design | NACE MR 0103, NACE MR 0175 |

Application

| Size | NPS1/2~NPS56 DN15~DN1400 |

| Pressure range | 150LB~2500LB、PN6~PN420 |

| Temperature range | ;-40°C ~ +600°C |

| Application range | Tap water, sewage, construction, petroleum, chemical industry, food, medicine, textile, electricity, shipbuilding, metallurgy, energy system, etc. |

| Drive mode | Turbine, pneumatic, electric |

| Valve body/valve bonnet | ASTM A105/ LF2, ASTM A182 F304/ F316/ F304L/ F316L |

| Valve core | ANSI304, A105/ENP |

| Valve stem | F6A F304 F316 F51 F53 Monel K500 |

| Valve stem nut | Copper Alloy |

| Packing | PTFE, PPL, RPTFE, Devlon, TEFLON |

Performance Features

The fully welded ball valve adopts a fully welded valve body structure and a proprietary valve seat (multiple sealing structure). Both designs help avoid leakage. The valve stem is designed to prevent blowout. If improper operation is encountered, the valve stem can be prevented from shooting out of the valve body.

The valve is equipped with fireproof and anti-static devices to effectively prevent fire. Grease injection valves are provided at the valve seat seal and the valve stem seal. When the sealing surface is damaged and causes leakage, sealing grease can be injected for emergency repair. Vent valves and drain valves are provided at the upper and lower parts of the valve body cavity to ensure safety, reliability and convenience.

Direct buried valves can be provided. Operators do not need to enter the well. They can use a T-handle on the well, which is convenient and safe. A relief valve structure can be set for easy management and safety.

About the valve seat piston effect: 1. Both upstream and downstream are single piston effect valve seats, that is, DBB function; 2. Both upstream and downstream are double piston effect valve seats, that is, DIB-1 function; 3. The upstream is a single piston effect valve seat, and the downstream is a double piston effect valve seat, that is, DIB-2 function.