- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

- Wafer Concentric Butterfly Valve

- Lug-Wafer Concentric Butterfly Valve

- Flange Concentric Butterfly Valve

- Double Eccentric Butterfly Valve

- Bronze Butterfly Valve

- Ball Valve

- Concentric Butterfly Valve

- PTFE Lined Butterfly Valve

- Gate Valve

- Globe Valve

- Butterfly Valve

- Cryogenic Valve

- Check Valve

- Automatic Control Valve

- PTFE Lined Valve

- Aluminum Bronze Valve

- Strainer Valve

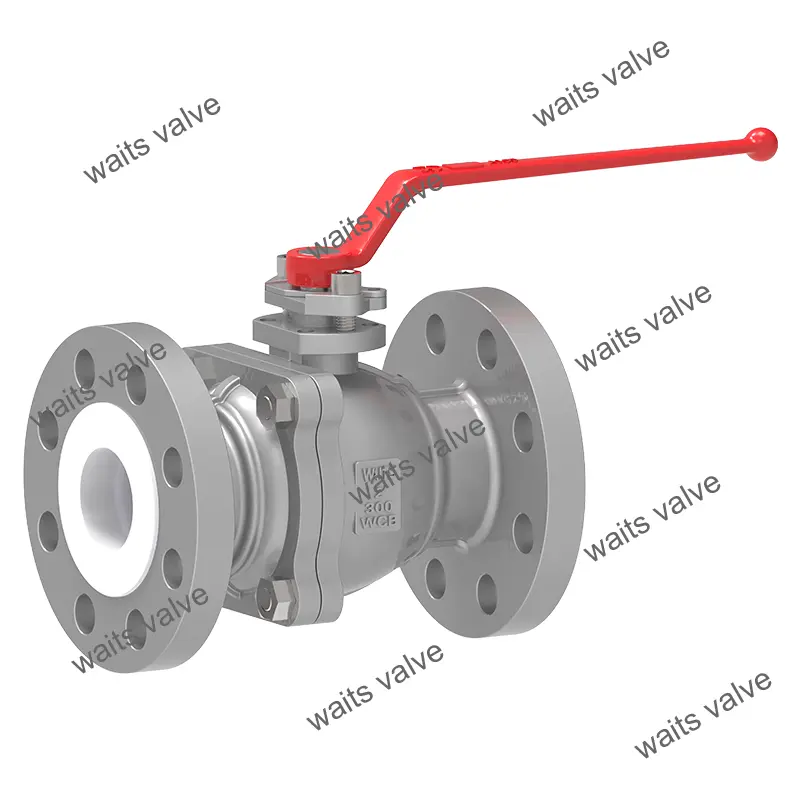

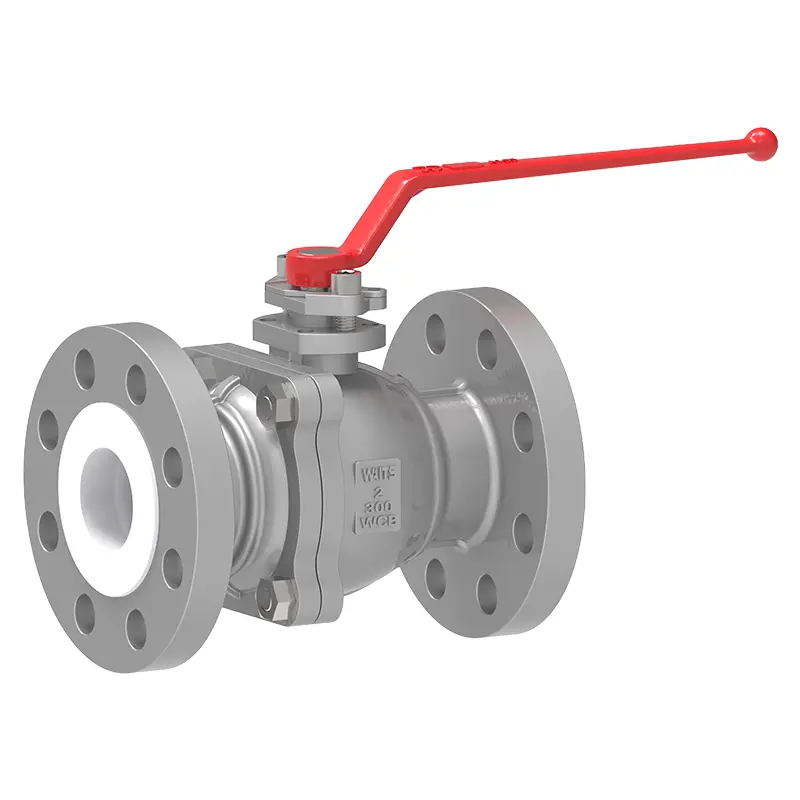

Level PTFE Lined Ball Valve

Waits Valve is the main manufacturer and supplier of Level PTFE Lined Ball Valve. With chemical resistance, reliable sealing, smooth operation and durable design, Level PTFE Lined Ball Valve can achieve precise flow control in harsh environments! Waits Valve is an expert in valves with stable quality. For 20 years, we have been committed to manufacturing durable general purpose valves.

Send Inquiry

When you need to control the opening and closing of highly corrosive media, I believe you will use our Waits Valve durable Level PTFE Lined Ball Valve. These valves are also equipped with anti blowout stem assemblies to prevent stem blowout even without top gear assemblies. Widely used in industries such as petroleum, chemical, printing and dyeing, pesticide manufacturing, acid and alkali production, it is the choice of corrosion resistant valves. These valves provide a variety of installation methods (flange, BW, NPT, etc.), and can be customized with corrosion-resistant materials (such as PTFE-lined stainless steel), explosion-proof design or fire-proof structure to meet the safety control requirements in different environments.

| Implementation Standards-Level PTFE Lined Ball Valve | |

| Design Standards | API 6D/API 608, BS5351 |

| Flange Standard | ASME B16.5/ASME B16.47-A/B /EN1092-1/2 |

| Connection methods | RF |

| Testing and acceptance | API 598, EN12266 |

| Structural length | API6D/ASME B16.10/EN558 |

| Pressure and temperature ratings | ASME B16.34 |

| Fireproof test | / |

| Low leakage standards | ISO 15848-1, API 622 |

| Anti-corrosion design | NACE MR 0175 |

| Application-Level PTFE Lined Ball Valve | |

| Size | DN6-DN150, NPS 1/4"-6" |

| Pressure range | ANSI CLASS 150-CLASS 300, PN1.0-PN2.0Mpa |

| Temperature range | PTFE-20°C~+180°C |

| Application range | Acid and alkali solution transportation, chemical reactor control, sewage/wastewater treatment, pharmaceutical, seawater, etc. |

| Drive mode | Handle |

| Valve body/valve cover |

Forgings: A105, A182 F304, F304L, F316, F316L, F51, F53, B148, A350 LF2, LF3, LF5, PTFE-lined Castings: DI A216 WCB, CF3, CF8, CF3M, CF8M, 4A, 5A, C95800, LCB, LCC, LC2, PTFE-lined |

| Sealing surface | PTFE |

| Valve stem | A182-F6a-F304-F316-F51 17-4PH/XM-19 ... |

| Ball | A105, A182 F304, F304L, F316, F316L, F51, F53, B148, A350 LF2, LF3, LF5, PTFE lined |

| Filler | Asbestos graphite, flexible graphite, polytetrafluoroethylene, iron-based alloy |

Product Maintenance Notes

1.Avoid forcing the handwheel (especially when jammed) to prevent damage to valve body or sealing surfaces.

2.Regularly check for looseness at the handwheel stem connection.

3.Prohibit operation under excessive temperature/pressure (fluoroplastics deform at high temperatures).

4.Inspect lining for damage (e.g., bubbles, cracks) during shutdowns and replace promptly.

Product Advantages

1.Manual open/close without tools.

2.Simple structure, ideal for budget-sensitive scenarios.

3.No wear prone transmission parts, minimal repairs needed.