- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

- Wafer Concentric Butterfly Valve

- Lug-Wafer Concentric Butterfly Valve

- Flange Concentric Butterfly Valve

- Double Eccentric Butterfly Valve

- Bronze Butterfly Valve

- Ball Valve

- Concentric Butterfly Valve

- PTFE Lined Butterfly Valve

- Gate Valve

- Globe Valve

- Butterfly Valve

- Cryogenic Valve

- Check Valve

- Automatic Control Valve

- PTFE Lined Valve

- Aluminum Bronze Valve

- Strainer Valve

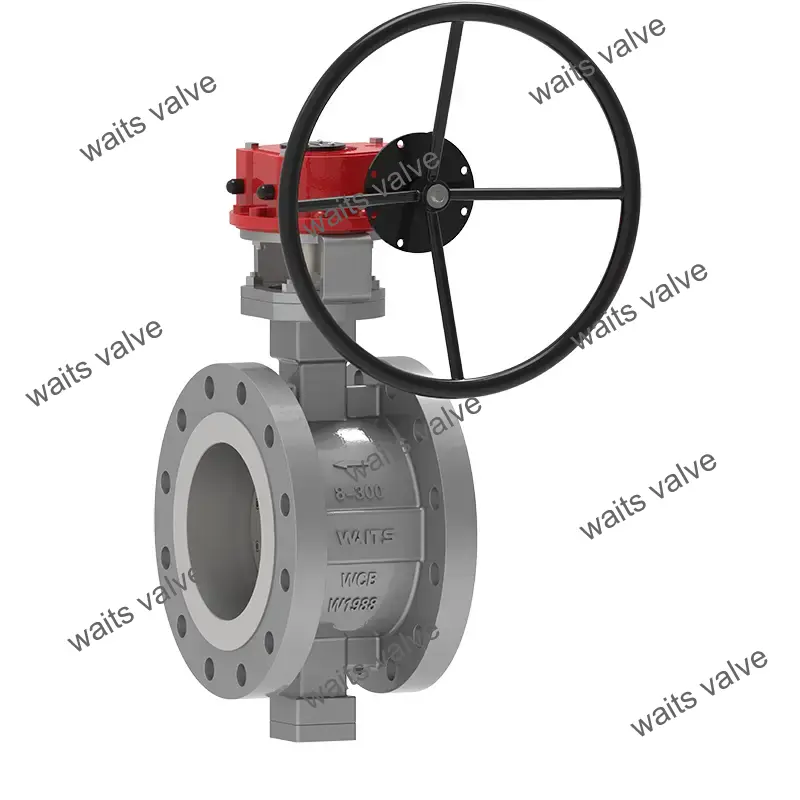

Triple Eccentric Metal Seated Flange Butterfly Valve

The triple eccentric metal seated flange butterfly valve is a valve produced and provided by Waits. It can adapt to higher temperature and pressure environments. The structure is designed with three-dimensional eccentric principle. It is especially favored by metallurgy, steel, electricity, petroleum, chemical industry, heating, gas and water supply and drainage projects in Central Asia.

Send Inquiry

The triple eccentric metal seated flange butterfly valve is a long-life, energy-saving butterfly valve, which is carefully designed by Waits' professional team and manufactured by precise and complete production equipment.

This valve consists of the main components such as the valve body, butterfly plate, sealing ring, transmission mechanism, etc. It adopts the two-dimensional or three-dimensional eccentric principle design, and actively applies new processing technology, such as elastic sealing or hard and soft multi-layer sealing.

When the butterfly valve is in operation, the torque is small, and the overall performance has reliable corrosion resistance, high temperature resistance, and wear resistance. It is an efficient and convenient valve product.

Implementation Standards

| Design Standard | API 609, EN 593, GOST |

| Flange standards | ASME B 16.5, ASME B16.47, EN 1092-1, GOST 54432, JIS 2220 |

| End Connection | RF, BW, RTJ, etc. |

| Inspection & Test | API 598, EN 12266-1, GOST |

| Face to Face | API 609, EN 558, ASME B16.10, GOST |

| Pressure and temperature levels | ASME B16.34 |

| Low leakage standards | ISO 15848-1, API 622 |

| Anti-corrosion design | NACE MR 0103, NACE MR 0175 |

Application

| Size | 3"-120", DN80-DN3000 |

| Pressure Rating | Class 150-1500, PN16-PN250 |

| Operating Temperature | Soft Seat: -29~200℃, Metal Seat: -29~600℃ |

| Application range | Tap water, sewage, construction, petroleum, chemical industry, food, medicine, textile, electricity, shipbuilding, metallurgy, energy system, etc. |

| Operator | Lever, Gear, Electric, Pneumatic, etc. |

| Body Material | Carbon Steel, Stainless Steel, Duplex Stainless Steel, Alloy Steel, Monel, Al Bronze, etc. |

| Valve plate | A216 WCB, A217 WC6, WC9, A351 CF3, CF8, CF3M, CF8M, A995 4A, 5A, A352 LCB, LCC, LC2, C95800,Monel... |

| Valve seat | 13Cr/SS304/SS316/+Graphites+PTFE+STL |

| Valve stem | F6A, F304, F316, 17-4PH, F51, F53, Monel K500... |

| Valve stem nut | Copper Alloy |

| Packing | Flexible graphite, graphite asbestos packing, polytetrafluoroethylene... |

Performance Features

1. Unique structural design, small and light, flexible and labor-saving in operation;

2. Good sealing performance, and strictly in accordance with various standards;

3. Good flow characteristics, with adjustment function;

4. The application of eccentric principle makes the sealing surface almost zero wear, reducing the frequency of maintenance and replacement;

5. Wide range of applications, can be used for various media including water, steam, oil, air and gas;

6. Suitable for pipelines of various working conditions such as different temperatures, grades, corrosion, etc., with powerful performance;

7. The valve body and valve seat of triple eccentric metal seated flange butterfly valve are connected components, and the valve seat sealing surface layer is made of surfacing heat-resistant and corrosion-resistant alloy material;

8. The three eccentricities are the deviation of the shaft center line from the sealing surface center line, the slight deviation of the shaft center line from the pipeline center line, and the valve body sealing surface (oblique cone) center line and the pipeline center line form an angle of angular position;

9. The multi-layer sealing ring is fixed on the valve plate, resistant to high temperature, and has no friction when opening and closing. When closing, the seal is compensated as the torque of the transmission mechanism increases. The use of soft and hard laminated metal sheets has the dual advantage of not affecting the sealing due to changes in temperature and environment.