- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

- Wafer Concentric Butterfly Valve

- Lug-Wafer Concentric Butterfly Valve

- Flange Concentric Butterfly Valve

- Double Eccentric Butterfly Valve

- Bronze Butterfly Valve

- Ball Valve

- Concentric Butterfly Valve

- PTFE Lined Butterfly Valve

- Gate Valve

- Globe Valve

- Butterfly Valve

- Cryogenic Valve

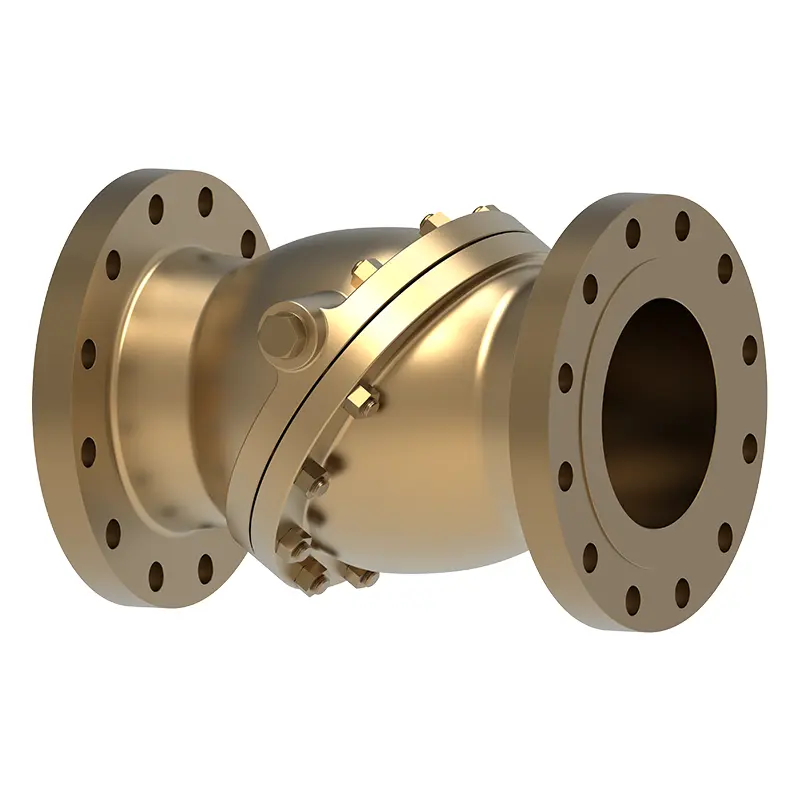

- Check Valve

- Automatic Control Valve

- PTFE Lined Valve

- Aluminum Bronze Valve

- Strainer Valve

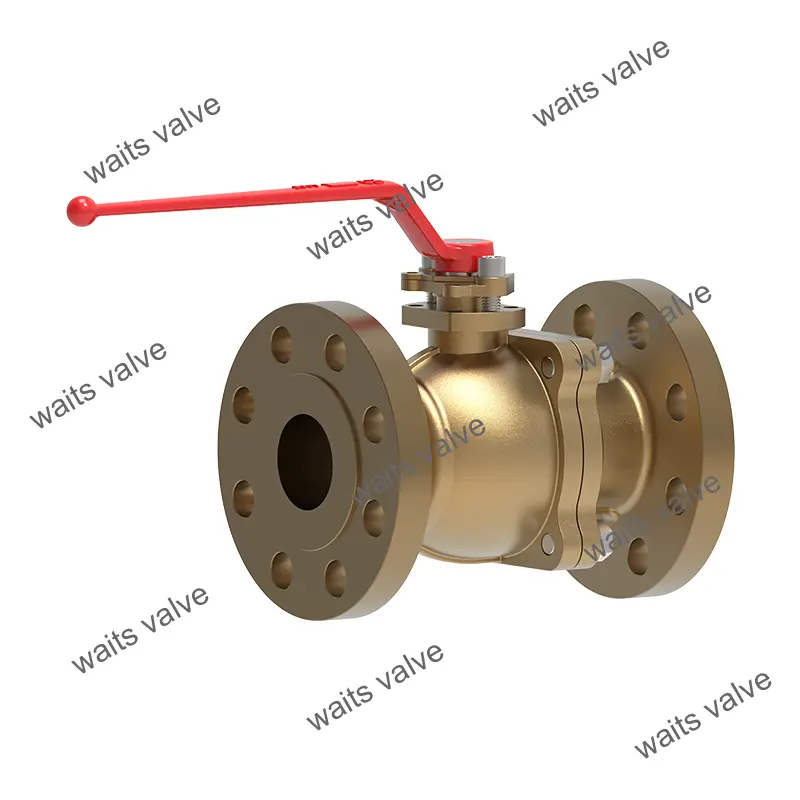

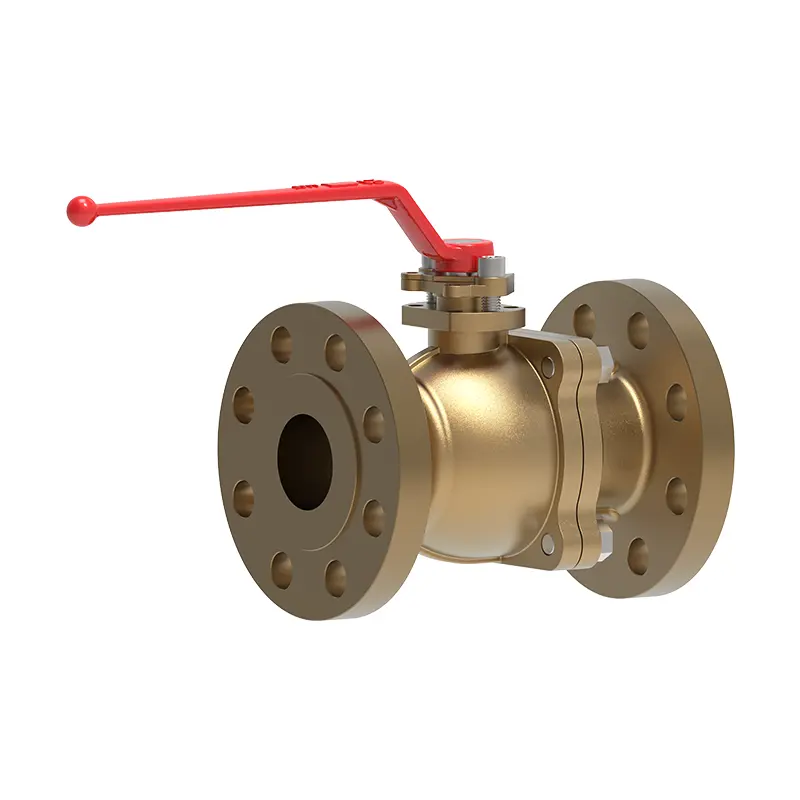

Bronze Level Floating Ball Valve

WAITS VALVE high quality Bronze Level Floating Ball Valve is widely used in building water supply and drainage systems, industrial cooling systems, agricultural irrigation and ship equipment. Choosing WAITS VALVE means choosing a "zero waiting, zero risk" service experience. WAITS VALVE converts every service detail into cost savings and efficiency improvement for customers.

Send Inquiry

The bronze material of WAITS VALVE durable Bronze Level Floating Ball Valve is an extremely special copper alloy chemical composition with good comprehensive properties such as strength, wear resistance, plasticity and corrosion resistance. Bronze valves are widely used in food, environmental protection, light industry, shipbuilding, chemical industry, petroleum, papermaking and power industries. When the size and pressure requirements are not high, it is economically and technically appropriate to use a bronze floating ball valve. In this case, the float is pushed to the outlet end, and a small pressure drop can ensure a good seal. Bronze has good castability, wear resistance and chemical stability. WAITS VALVE provides complete product services and preferential prices, and is your choice for procurement.

| Implementation Standards-Bronze Level Floating Ball Valve | |

| Design standards | API 6D/API 608, BS5351 |

| Flange standards | ASME B16.5/ASME B16.47-A/B /EN1092-1/2 |

| Connection methods | RF, NPT, FNPT |

| Testing and acceptance | API 598, EN12266 |

| Structural length | API6D/ASME B16.10/EN558 |

| Pressure and temperature ratings | ASME B16.34 |

| Fireproof test | API 6FA, API 607 |

| Low leakage standards | ISO 15848-1, API 622 |

| Anti-corrosion design | NACE MR 0175 |

|

|

|

| Application-Bronze Level Floating Ball Valve | |

| Size | NPS 2″~ NPS 6″ DN50~ DN150 |

| Pressure range | ANSI CLASS150~ANSI CLASS1500 PN10 ~ PN260 |

| Temperature range | -20℃~350℃ |

| Application range | Tap water, sewage, construction, petroleum, chemical industry, food, medicine, textile, electricity, shipbuilding, metallurgy, energy system, etc. |

| Drive mode | Hydraulic, pneumatic, electric, manual and worm gear transmission. |

| Valve body/valve cover | C95200、C95400、C95500、C63000、C83600、QA19-4、 |

| Sealing surface | Reinforced polytetrafluoroethylene, para-polyphenylene (RPTFE, PPL), Metal |

| Valve stem | C95200, C95400, C95500, C63000, C83600, QA19-4, |

| Valve stem nut | Copper alloy |

| Filler | Asbestos graphite, flexible graphite, polytetrafluoroethylene, iron-based alloy |

Product Advantages

1. Bronze alloy performs well in corrosive environments such as seawater and chemical media, and is suitable for marine engineering, chemical pipelines and other occasions.

2. The ball of the floating ball valve automatically presses the outlet valve seat under the pressure of the medium to form a dynamic seal. Combined with the wear resistance of bronze, a higher sealing level (such as zero leakage) can be achieved. The composite design of soft sealing materials (such as PTFE or PPL) and metal hard seals further optimizes the sealing effect.

3. The Bronze Level Floating Ball Valve is small in size and light in weight, and can be quickly opened and closed by rotating 90°. The manual operation torque is small, which is suitable for occasions with frequent switching. The high strength characteristics of bronze also enhance the stability of the overall structure of the valve.

4. The floating ball valve adopts a modular design, and the sealing ring can be replaced independently. The wear resistance of bronze extends the maintenance cycle and reduces the long term use cost.