- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

- Wafer Concentric Butterfly Valve

- Lug-Wafer Concentric Butterfly Valve

- Flange Concentric Butterfly Valve

- Double Eccentric Butterfly Valve

- Bronze Butterfly Valve

- Ball Valve

- Concentric Butterfly Valve

- PTFE Lined Butterfly Valve

- Gate Valve

- Globe Valve

- Butterfly Valve

- Cryogenic Valve

- Check Valve

- Automatic Control Valve

- PTFE Lined Valve

- Aluminum Bronze Valve

- Strainer Valve

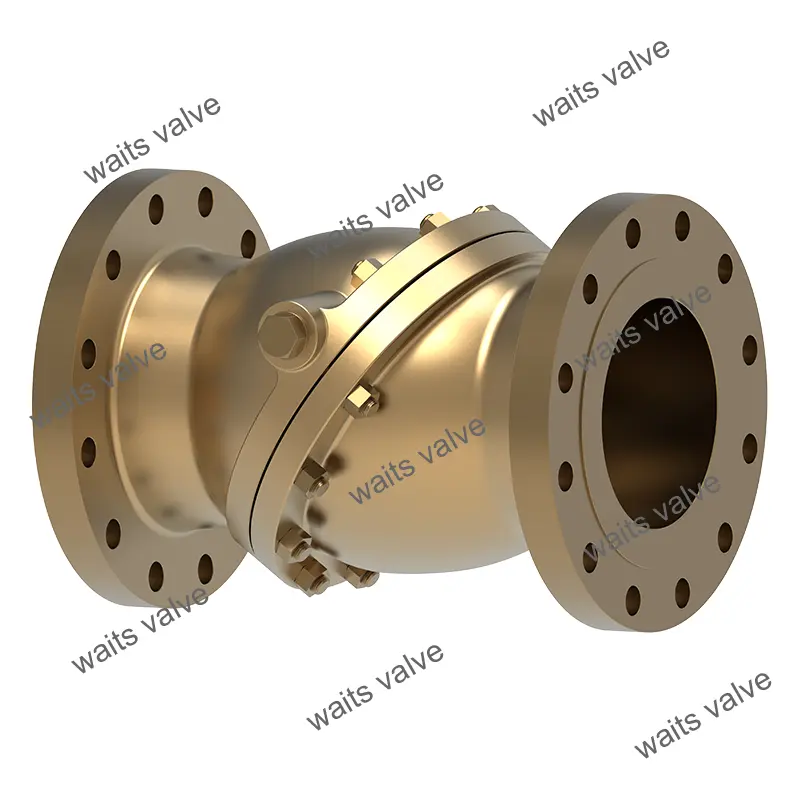

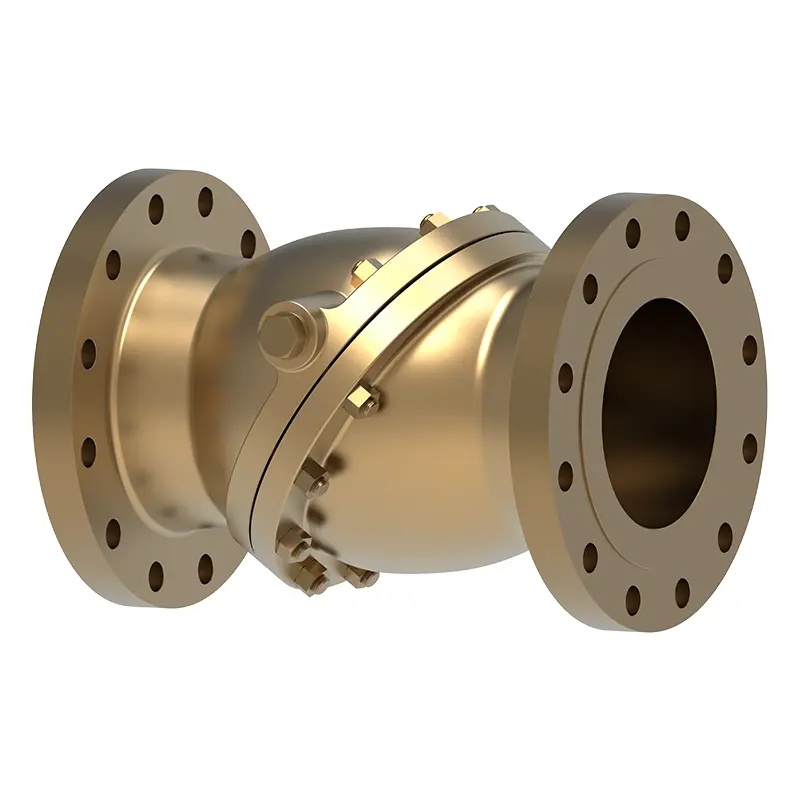

Bronze Tilted Disc Check Valve

Bronze Tilted Disc Check Valve is made of high quality bronze, which is not easily corroded. It is widely used in seawater, fresh water, cooling systems, shipbuilding engineering, industrial equipment and other fields. Waits Valve complies with the ISO9001 quality management system, and the high quality valves designed and produced can withstand extreme operational challenges. We have become a long term partner of energy companies in more than 30 countries.

Send Inquiry

Waits Valve Bronze Tilted Disc Check Valve is a one way check device with exquisite structure, high quality and durability. It adopts an inclined disc design, which opens in forward flow and closes quickly in reverse flow. It is suitable for preventing medium backflow in medium and low pressure pipeline systems. It has the best cost effectiveness in specific environments.

Bronze Tilted Disc Check Valve adopts an inclined disc structure to achieve one way control of fluid. It is made of wear resistant, corrosion resistant and high strength bronze. It is suitable for pipeline systems that have high requirements for fluid flow stability and need to avoid water hammer, such as cooling systems of some precision equipment, water supply systems of high rise buildings, and pump outlets or water supply and drainage systems with water or oil as the medium.

| Implementation Standards-Bronze Tilted Disc Check Valve | |

| Design Standards | API 6D/API 594, BS1868 |

| Flange Standard | ASME B16.5/ASME B16.47-A/B /EN1092-1/2 |

| Connection methods | RF, NPT, FNPT |

| Testing and acceptance | API 598, EN12266 |

| Structural length | API6D/ASME B16.10/EN558 |

| Pressure and temperature ratings | ASME B16.34 |

| Fireproof test | API 6FA, API 607 |

| Low leakage standards | ISO 15848-1, API 622 |

| Anti-corrosion design | NACE MR 0175 |

|

|

|

| Application-Bronze Tilted Disc Check Valve | |

| Size | DN50-DN1200, NPS 2"48" |

| Pressure range | ANSI CLASS 150-CLASS 600, PN2.0-PN10.0Mpa |

| Temperature range | -20℃~425℃ |

| Application range | Seawater, polycarbonate, polyethylene, low-density polyethylene, aromatic hydrocarbons, liquefied natural gas (LNG) |

| Drive mode | Hydraulic, pneumatic, electric, manual and worm gear drives. |

| Valve body/valve cover | C95200, C95400, C95500, C63000, C83600, QA19-4, |

| Sealing surface | Reinforced polytetrafluoroethylene, para-polyphenylene (RPTFE, PPL), Metal |

| Filler | Asbestos graphite, flexible graphite, polytetrafluoroethylene, iron-based alloys |

Product Advantages

1. Bronze Tilted Disc Check Valve adopts double eccentric disc design, and the valve seat and the sealing surface gradually contact during the closing process, so that noise can be eliminated. The large noise generated when the traditional check valve is closed is eliminated, which prolongs the service life of pipelines and equipment.

2. Micro elastic metal valve seat design, this design can prevent leakage and prevent medium backflow, allowing the normal operation of the pipeline system.

3. The inclined disc structure forms a streamlined fluid channel with a low flow resistance coefficient, which greatly reduces the pressure loss when the medium flows through the valve and reduces the operating cost of the pipeline system.

4. The butterfly disc design is sensitive to opening and closing, so that the valve can quickly adapt to changes in medium flow, open and close in time, and prevent backflow.

5. Compared with the swing check valve of the same caliber, the Bronze Tilted Disc Check Valve is about 80% lighter, and our valve is more convenient in installation, disassembly and maintenance, which reduces the pipeline load.