- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

- Wafer Concentric Butterfly Valve

- Lug-Wafer Concentric Butterfly Valve

- Flange Concentric Butterfly Valve

- Double Eccentric Butterfly Valve

- Bronze Butterfly Valve

- Ball Valve

- Concentric Butterfly Valve

- PTFE Lined Butterfly Valve

- Gate Valve

- Globe Valve

- Butterfly Valve

- Cryogenic Valve

- Check Valve

- Automatic Control Valve

- PTFE Lined Valve

- Aluminum Bronze Valve

- Strainer Valve

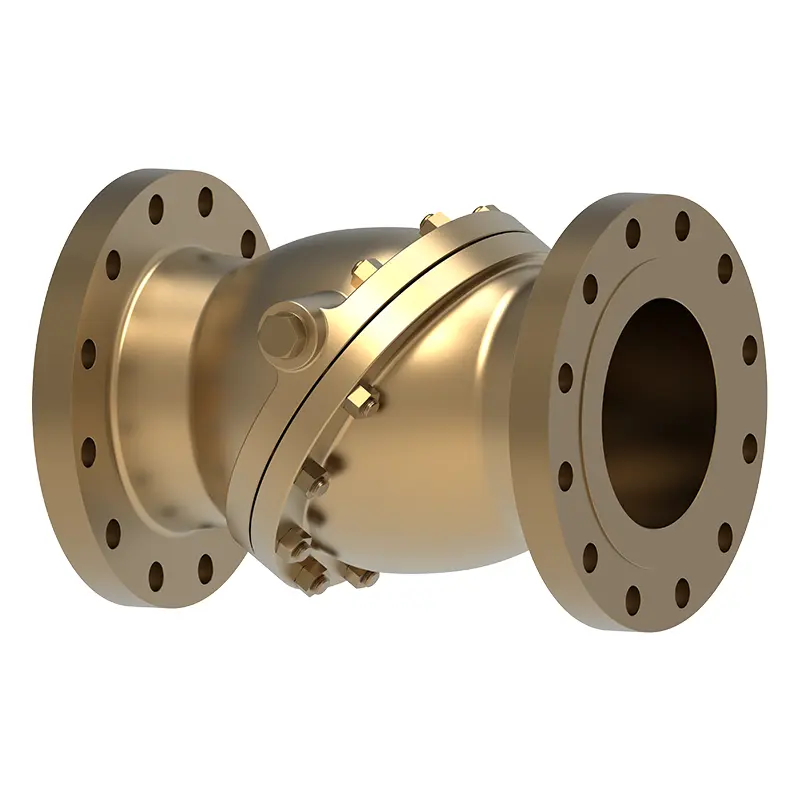

Bronze Turnnion Ball Valve

Waits Valve offers the advanced Bronze Turnnion Ball Valve, a high performance ball valve with a fixed ball structure and bidirectional sealing design. Unlike floating ball valves, the ball of this valve is fixed by upper and lower "bearing supports" and does not move with pressure, making it suitable for opening and closing control under high pressure, large diameter or severe working conditions. Waits Valve has established a global leading position with innovative product engineering, strict quality assurance procedures and predictive service systems.

Send Inquiry

The valve body of Waits Valve Bronze Turnnion Ball Valve is made of high quality corrosion resistant bronze, which is particularly suitable for working conditions such as seawater, salt water, and low corrosive chemical media. In the bronze fixed ball valve, the fixed ball realizes axial sealing along the axis of the flow channel, so that the sealing seat is not prone to excessive friction. It is widely used in marine engineering, shipbuilding, water treatment, cooling systems and industrial process control.

| Implementation Standards-Bronze Turnnion Ball Valve | |

| Design standards | API 6D/API 608, BS5351 |

| Flange standards | ASME B16.5/ASME B16.47-A/B /EN1092-1/2 |

| Connection methods | RF, NPT, FNPT |

| Testing and acceptance | API 598, EN12266 |

| Structural length | API6D/ASME B16.10/EN558 |

| Pressure and temperature ratings | ASME B16.34 |

| Fireproof test | API 6FA, API 607 |

| Low leakage standards | ISO 15848-1, API 622 |

| Anti-corrosion design | NACE MR 0175 |

|

|

|

| Application-Bronze Turnnion Ball Valve | |

| Size | DN6-DN900, NPS 1/4"-36" |

| Pressure range | ANSI CLASS 150-CLASS 900, PN1.0-PN32.0Mpa |

| Temperature range | -20℃~350℃ |

| Application range | Tap water, sewage, construction, petroleum, chemical industry, food, medicine, textile, electricity, shipbuilding, metallurgy, energy system, etc. |

| Drive mode | Hydraulic, pneumatic, electric, manual and worm gear transmission. |

| Valve body/valve cover | C95200, C95400, C95500, C63000, C83600, QA19-4, |

| Sealing surface | Reinforced polytetrafluoroethylene, para-polyphenylene (RPTFE, PPL), Metal |

| Valve stem | C95200, C95400, C95500, C63000, C83600, QA19-4, |

| Valve stem nut | Copper alloy |

| Filler | Asbestos graphite, flexible graphite, polytetrafluoroethylene, iron-based alloy |

Product performance feature:

Excellent performance in corrosive environments (seawater, chemical media) with long term oxidation resistance and biofouling prevention, suitable for marine engineering and chemical pipelines.Trunnion mounted design secures the ball with axial bearings, preventing pressure induced displacement and ensuring uniform sealing surface wear, ideal for high pressure and large diameter applications.Combines soft/hard sealing structures to achieve leakage rates <0.01% while maintaining long term sealing integrity.High wear resistance and thermal stability minimize maintenance frequency caused by abrasive media or thermal stress.

Application areas

Ship and offshore platform piping systems

Cooling systems and heat exchangers

Water treatment and filtration devices

Industrial process pipeline automation

Port and seawater desalination systems

Control of low-corrosive fluids in petroleum and chemical transportation