- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

China PTFE Lined Valve Manufacturer, Supplier

- View as

Gear PTFE Lined Ball Valve

Waits Valve is a professional Gear PTFE Lined Ball Valve supplier in China. Our product has solid gear transmission precision, PTFE lining is corrosion-resistant, the structure is durable, and the sealing is very good, which can achieve efficient flow control in harsh industrial environments! Waits Valve's large-scale procurement reduces the cost of raw materials.

Read MoreSend InquiryLevel PTFE Lined Ball Valve

Waits Valve is the main manufacturer and supplier of Level PTFE Lined Ball Valve. With chemical resistance, reliable sealing, smooth operation and durable design, Level PTFE Lined Ball Valve can achieve precise flow control in harsh environments! Waits Valve is an expert in valves with stable quality. For 20 years, we have been committed to manufacturing durable general purpose valves.

Read MoreSend Inquiry

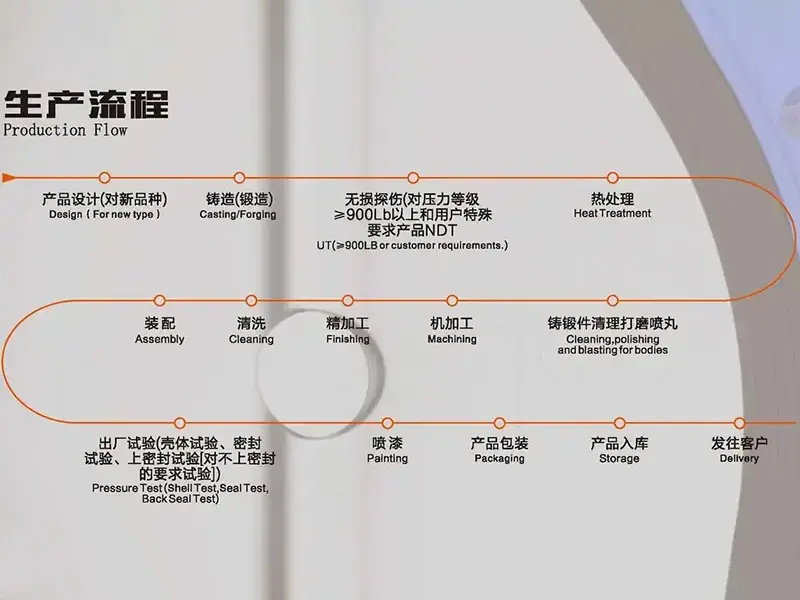

Processes for Manufacturing Waits Fluorine-Lined Valves

1. Isostatic Molding Method

The isostatic molding method refers to a forming process that achieves the lining effect under the condition of equal pressure difference between the inner and outer walls of all lined parts of the workpiece. The biggest difference between this molding method and traditional compression molding lies in achieving the condition of equal pressure difference between the inner and outer walls of the workpiece's lined parts during the pressing process.

2. Compression Molding Process

The compression molding process employs medium-particle-size suspension polytetrafluoroethylene (PTFE) resin as the material. Molding initiates at approximately 19-22°C; higher temperatures may lead to material agglomeration, and precise temperature control is crucial to eliminate internal stress during this stage. Pressure is typically regulated at 350 kg/cm² and sustained according to the workpiece's size and shape. The process concludes with a three-stage sintering procedure—heating, holding, and cooling—after which machining is performed to achieve the desired specifications.

3. Transfer Molding Process

The transfer molding process involves placing the quality Waits valve body and the lining material together in a high-temperature sintering furnace for heating. After heating to a certain temperature, the body is taken out, and the lining material is slowly transferred to all parts of the lined body under the pressure of a press. This forming method is called transfer molding.

Fluorine-lined valves are classified as follows:

Pinch valves, lined diaphragm valves, lined pneumatic butterfly valves, lined pneumatic ball valves, lined check valves, fluorine-lined globe valves, lined plug valves, lined wedge gate valves, diaphragm valves, butterfly valves, ball valves, swing check valves, ball core check valves, pneumatic rubber-lined valves, fluorine-lined plastic diaphragm valves (normally closed type), straight-through fluorine-lined diaphragm valves, packed adjustable fluorine-lined plastic butterfly valves, fluorine-lined plastic globe valves, etc.

Production Process Management of Waits Valve

Waits Valve builds strong service and quality systems using practical methods. We follow strict industry standards like API 6D and CE-PED, and use ISO quality (9001), environmental (14001), and safety (45001) systems in all production steps. This ensures consistent operations and full tracking of every product.For quality checks, we use modern pressure-testing machines to verify valve strength. Smart inspection tools carefully check important parts like surfaces and seals to prevent quality issues. By combining strict management with detailed testing, we create reliable fluid control solutions for industries.

For more product details or technical assistance, please contact our expert team at any time.