- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

- Wafer Concentric Butterfly Valve

- Lug-Wafer Concentric Butterfly Valve

- Flange Concentric Butterfly Valve

- Double Eccentric Butterfly Valve

- Bronze Butterfly Valve

- Ball Valve

- Concentric Butterfly Valve

- PTFE Lined Butterfly Valve

- Gate Valve

- Globe Valve

- Butterfly Valve

- Cryogenic Valve

- Check Valve

- Automatic Control Valve

- PTFE Lined Valve

- Aluminum Bronze Valve

- Strainer Valve

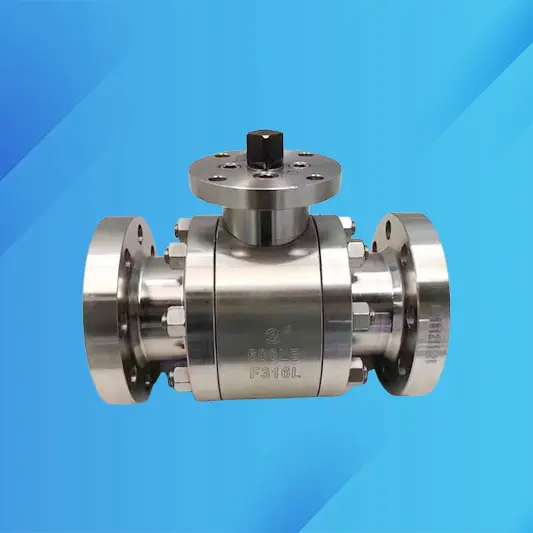

China Ball Valve Manufacturer, Supplier

WAITS VALVE - Your trusted source for high-quality valves. As a leading valve supplier, we take pride in offering a wide range of valves to suit different needs. Known for precision engineering and superior quality, our products range from ball valves to gate valves. Discover the WAITS VALVE difference and feel free to send us inquiries to get the competitive price.

Ball valves are very versatile. They allow, hinder and control the flow of liquids, gases and steam in pipe systems by rotating a ball with a hole. The ball is mounted on two valve seats, connected by a valve stem, and the operation of rotating the ball is performed by a control mechanism. When the direction of the hole is completely perpendicular to the direction of the fluid in the pipe, the fluid is not allowed to pass through the valve. The speed of the fluid depends on the angle of rotation of the ball. Like plug valves and butterfly valves, ball valves are also quarter-angle rotary valves. They can be operated manually or by an actuator. The simplest operation is to use a wrench or lever and rotate it manually by the operator. Applying torque rotates the lever arm 90 degrees clockwise or counterclockwise to open or close the valve. If the lever arm is parallel to the pipe, it means that the valve is open. If the lever arm is perpendicular to the pipe, the valve is closed.

Our ball valve can be manufactured in different standards according to customer requirements, such as API6D/ ISO17292/BS5351, and strictly follow the standard manufacturing and acceptance. In the oil field projects in the Middle East and Southeast Asia, many double block and bleed ball valves of WAITS VALVE are still serving customers. The super fast delivery time of WAITS VALVE is also one of the reasons why customers choose us.

- View as

Gear PTFE Lined Ball Valve

Waits Valve is a professional Gear PTFE Lined Ball Valve supplier in China. Our product has solid gear transmission precision, PTFE lining is corrosion-resistant, the structure is durable, and the sealing is very good, which can achieve efficient flow control in harsh industrial environments! Waits Valve's large-scale procurement reduces the cost of raw materials.

Read MoreSend InquiryLevel PTFE Lined Ball Valve

Waits Valve is the main manufacturer and supplier of Level PTFE Lined Ball Valve. With chemical resistance, reliable sealing, smooth operation and durable design, Level PTFE Lined Ball Valve can achieve precise flow control in harsh environments! Waits Valve is an expert in valves with stable quality. For 20 years, we have been committed to manufacturing durable general purpose valves.

Read MoreSend InquiryElectric Top Entry Ball Valve

The electric top entry ball valve produced and manufactured by Waits is a high-performance, high-quality valve product, which is designed, produced and inspected strictly in accordance with API standards. We were founded in the United States in 1994, entered China in 2008 and finally established our global headquarters in Wenzhou. We have the ability to provide cost-effective products to customers in the world market.

Read MoreSend InquiryPneumatic Floating Ball Valve

Pneumatic floating ball valve is a pneumatic valve product of Waits, with high performance, cheap factory price, stable supply and comprehensive service and support. We fully consider the needs of different customers in valve manufacturing, and can adopt API602/ISO17292/BS5351 and other standards, and manufacture and accept according to standards throughout the process to ensure product quality.

Read MoreSend InquiryPneumatic Trunnion Ball Valve

Waits is a pneumatic trunnion ball valve manufacturer with its global headquarters in China. We can provide customers in the world market with a stable supply and competitive prices. Rich industry experience and professional team help us further improve product quality and related service levels. Different manufacturing standards can be used in production, such as API6D/ISO17292/BS5351, etc.

Read MoreSend Inquiry2 PCS Flange Floating Ball Valve

Waits Valve's 2 PCS Flange Floating Ball Valve complies with API 608 and ISO 17292 standards. It also adopts lever operation, easy operation, and has safety designs such as anti static valve stem, suitable for petrochemical, natural gas and power industries. Its floating ball structure presses the valve seat under fluid pressure to achieve tight closure, suitable for on-off control of various pipelines.

Read MoreSend Inquiry

Ball valve is a efficient valve that control the fluids flow and blockage by rotate the ball.Valves has core advantages such as simple structure, good sealing performance, and convenient operation, and the valve is widely used in industries such as petroleum, chemical engineering, power and water treatment. The working principle of ball valve made in China is to achieve the opening and cutting off of the fluid by rotating the ball with a through-hole 90° under the pressure of the medium. The characteristics of WAITS ball valve is low flow resistance, fast opening and closing, and long service life.

According to the different structural designs, ball valves are mainly divided into the following types:

Floating ball valve : The ball is pressed against the valve seat seal under the pressure of the medium, suitable for small-diameter and medium-pressure working conditions, and the durable ball valve is economical and practical.

Fixed Ball Valve : The ball of WAITS quality ball valve is supported by the upper and lower fixed shafts, suit the high pressure and sealing stable, The classy ball valve is the first choice for long-distance pipelines of petroleum and natural gas.

V-ball valve : The ball has a V-Port, which can precisely regulate the flow rate, and is special suitable for high-viscosity media such as slurries and powders.

Double ball valve: The double-ball design in WAITS advanced ball valve make the double sealing safer, and is suitable for high-risk media such as liquefied natural gas (LNG).

Side-entry ball valve: The body can be disassembled from the side, facilitating maintenance, and is suitable for installation environments with limited space.

Top Entry ball valve : The top is detachable, making maintenance convenient, and does not require disassembling the entire valve, suitable for buried or elevated pipelines.

| Structural type | Advantages | Limitations | Typical applications |

| Floating ball valve | Low cost, lightweight | High pressure and large torque | Small-diameter water/gas pipelines |

| Fixed ball valve | High pressure stability, Bidirectional sealing | Complex structure, high price | Long-distance pipelines of petroleum and natural gam |

| Three-piece ball valve | Maintenance convenient | Large volume, high weight | Corrosive media in chemical industry |

| V-port ball valve | Precise flow regulation | Not resistant to particle wear | Flow control of slurries and powders |

| Three-way T-port ball valve | Multi-directional control | High flow resistance | Reaction vessel mixing system |

Core Product Advantages

1. Flange Floating Ball Valve

It ensures excellent sealing performance with a precisely machined floating ball structure. The body is available in multiple grades to meet the requirements of different media. The working pressure can reach PN40, and the applicable temperature range is from -29°C to 200°C. Typical applications: urban water supply and drainage, food processing, and pharmaceutical industries.

2. Fixed Ball Valve

Full bore design of Newest Ball Valve with a flow resistance coefficient as low as 0.05. Double piston effect valve seat ensures reliable sealing under high-pressure conditions. Complies with API 6D standards, with the highest pressure rating up to ASME 2500#. Typical applications: long-distance pipelines, LNG receiving stations, and refining and chemical plants.

3. Two-Piece Welded Ball Valve

Full welded body structure of Advanced Ball Valve for zero leakage. Buried design with an extended valve stem for underground operation. Certified by ISO 15848 micro-leakage. Typical applications: urban gas pipelines and chemical parks.

Differentiated Service System

1. Agile Response Mechanism

Professional customer service team provides 7×24-hour technical consultation.

Standard product quotation response time < 4 hours.

Emergency order processing cycle can be shortened to 72 hours.

2. Full Lifecycle Service

Pre-sale stage: Provide fluid flow analysis and valve selection consultation.

Sale stage: Offer installation guidance and on-site commissioning services.

After-sale stage: Provide maintenance and repair services, as well as spare parts supply.

3. Customized Solutions

Special materials (such as Inconel, Hastelloy) valves can be provided

Customization for non-standard sizes and special connection methods is supported

Quality Assurance System

Obtained multiple certifications including API 6D, CE, ISO 9001, etc.

100% factory pressure testing, using fully automatic pressure testing equipment

Traceability system for key components to ensure quality consistency

WAITS Valves adhere to the business philosophy of "Customer-Centricity", through continuous technological innovation and service optimization, creating maximum value for customers. We look forward to developing together with global partners and providing safer and more efficient solutions in the field of industrial fluid control.

If you need to obtain more product information or technical support, please feel free to contact our professional team at any time.