- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

China Wafer Type Dual Plate Check Valve Manufacturer, Supplier

owing to excellent support, a variety of top of the range items, aggressive rates and efficient delivery, we enjoy a very good reputation among our clients. We have been an energetic firm with wide market for Wafer Type Dual Plate Check Valve,Double Disc Check Valve,Dual Flap Check Valve,Resilient Seated Dual Plate Check Valve,Low Pressure Dual Plate Check Valve, We sincerely welcome domestic and foreign merchants who calls, letters asking, or to plants to negotiate, we will offer you quality products and the most enthusiastic service,We look forward to your visit and your cooperation.

Wafer Type Dual Plate Check Valve, We've got more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information make sure you do no hesitate to contact us.

Hot Products

Angle Globe Valve

When you are faced with a unique 90-degree flow channel piping system, you must think of Waits Valve high quality Angle Globe Valve, which has a wide range of applications. We specially use a compact design to save space and simplify pipeline routing. When you are faced with a small space or limited installation, you can use this valve.Bronze Wafer Butterfly Valve

Waits Valve Ltd.'s Bronze Wafer Butterfly Valve is a rotary valve with a visual indication of whether the valve is fully open. With an advanced double or triple eccentric design that effectively reduces seal surface wear and lowers operating torque, you can use this valve for years for one dollar, come and negotiate business with us!Three-Piece Pneumatic Floating Ball Valve (with Bracket)

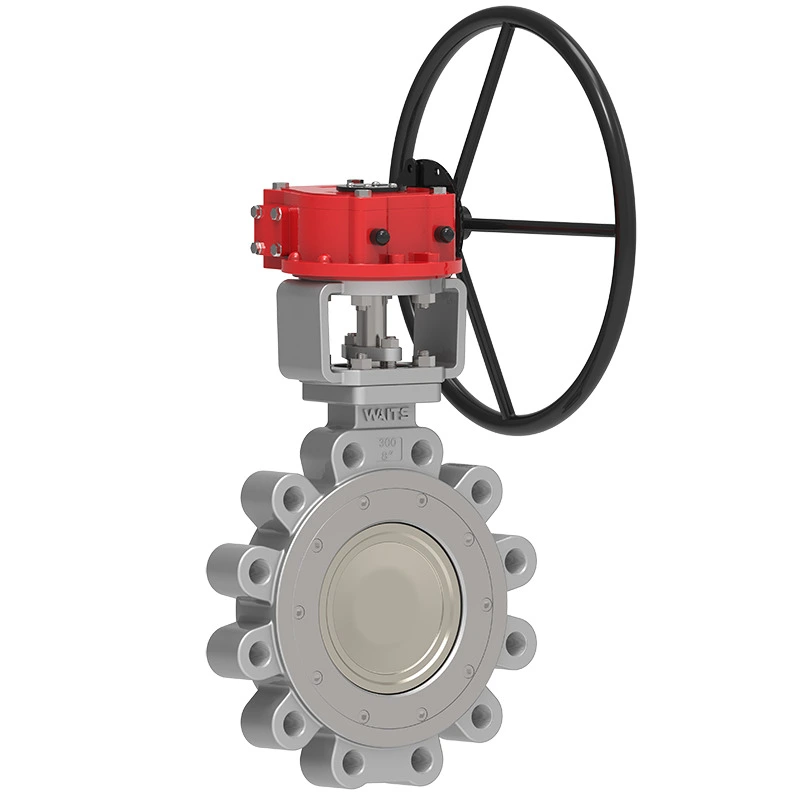

Waits Valve Three-Piece Pneumatic Floating Ball Valve (with Bracket) is ISO and API certified and has undergone rigorous pressure/seal testing. The pneumatic actuator uses an internal hard anodized and external extruded aluminum housing with epoxy coated end caps. Such materials and design are very corrosion-resistant. I believe that when you encounter other simple valves, you will regret not choosing Waits Valve's valve!Gear Flange Concentric Butterfly Valve

Gear Flange Concentric Butterfly Valve can be customizable for different installations; internal support seat prevents disc sag and leakage in vertical mounting. Available up to DN2400 (96").Lever Signal Actuated Wafer Butterfly Valve Touch Active

Waits Valve's high-quality lever single-actuated wafer butterfly valve (touch-activated) is available with standard on-off or modulating quarter-turn electric actuators. The V4 series also offers dry contacts for on-off feedback output signals; the modulating feedback output signal can be selected via a DIP switch to 0-5V, 0-10V, or 4-20mA. Custom orders are welcome!